Remote controll

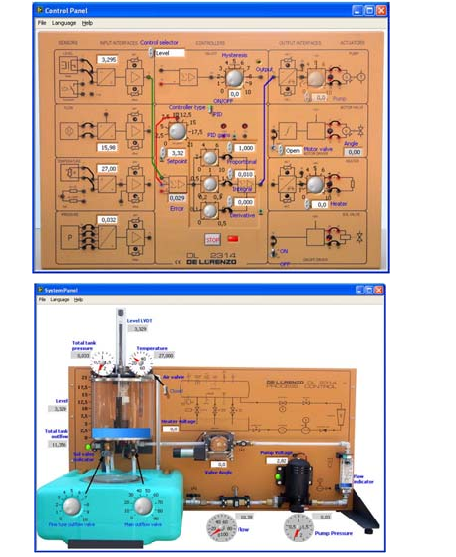

Users can influence the operation of the system through the controller. The system is controlled by the following parameters of the actuator:

- Pump: input voltage (0V to 10V)

- Pump motor control: angle (0 ° to 40 °)

- Heating resistance: input voltage (0V to 10V)

and treatment tank: - Output valve 1: angle (0 ° to 90 °)

- Output valve 2: number of rpm

- Solenoid valve: on or off

- Gas valve: on or off

The controller consists of PID and On / Off controls which are used to control the temperature of water, its pressure and its level inside the treatment tank.

Parameters can also be controlled manually.

The system is controlled

The system is a teaching device consisting of a pressure-processing tank, storage tank and a sensor and actuator for measuring level, pressure, temperature and flow.

The behavior of the system is modeled on the basis of the characteristics of physical components. Under a given supply voltage, the pump generates a water flow that is also dependent on the pressure in the system. In the treatment tank, a quantity of water can be stored and put hydrostatic pressure at the bottom. The treatment tank is also equipped with an air valve that can be used to control the pressure of the air inside the tank.

Therefore, the outlet pressure from the tank is the sum of hydrostatic pressure and air pressure. The temperature of the water inside the treatment tank can be controlled by heating resistors. To influence the pressure in the system, valves may also be used. The tank is used to store water for the system and has atmospheric pressure at its outlet.

The simulator calculates and presents the user with the following parameters:

- Traffic in the system

- Outflow from the treatment tank

- Pressure caused by the pump

- Total pressure at the outlet of the tank

- Water level in treatment tank

- The temperature of the water in the treatment tank