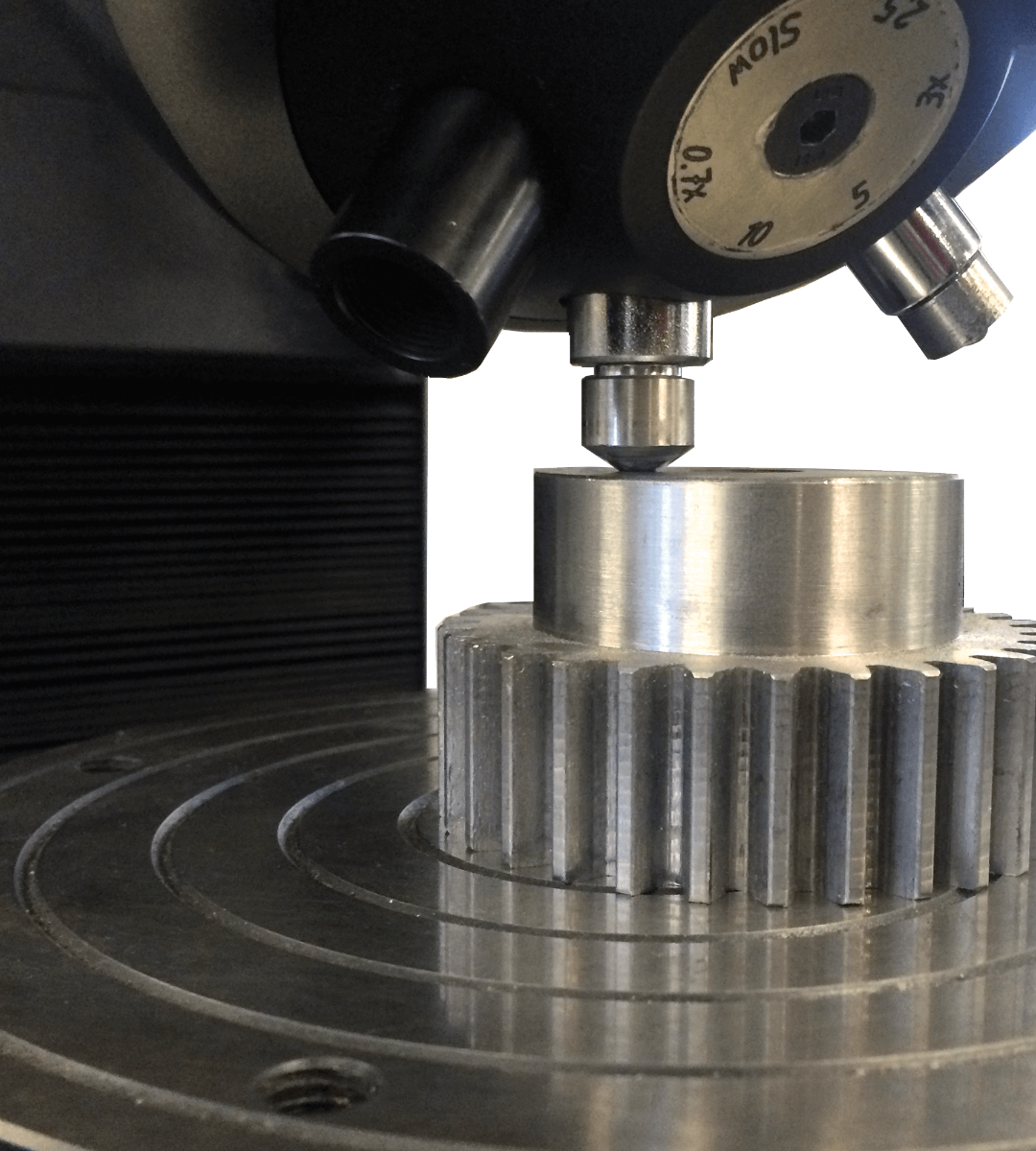

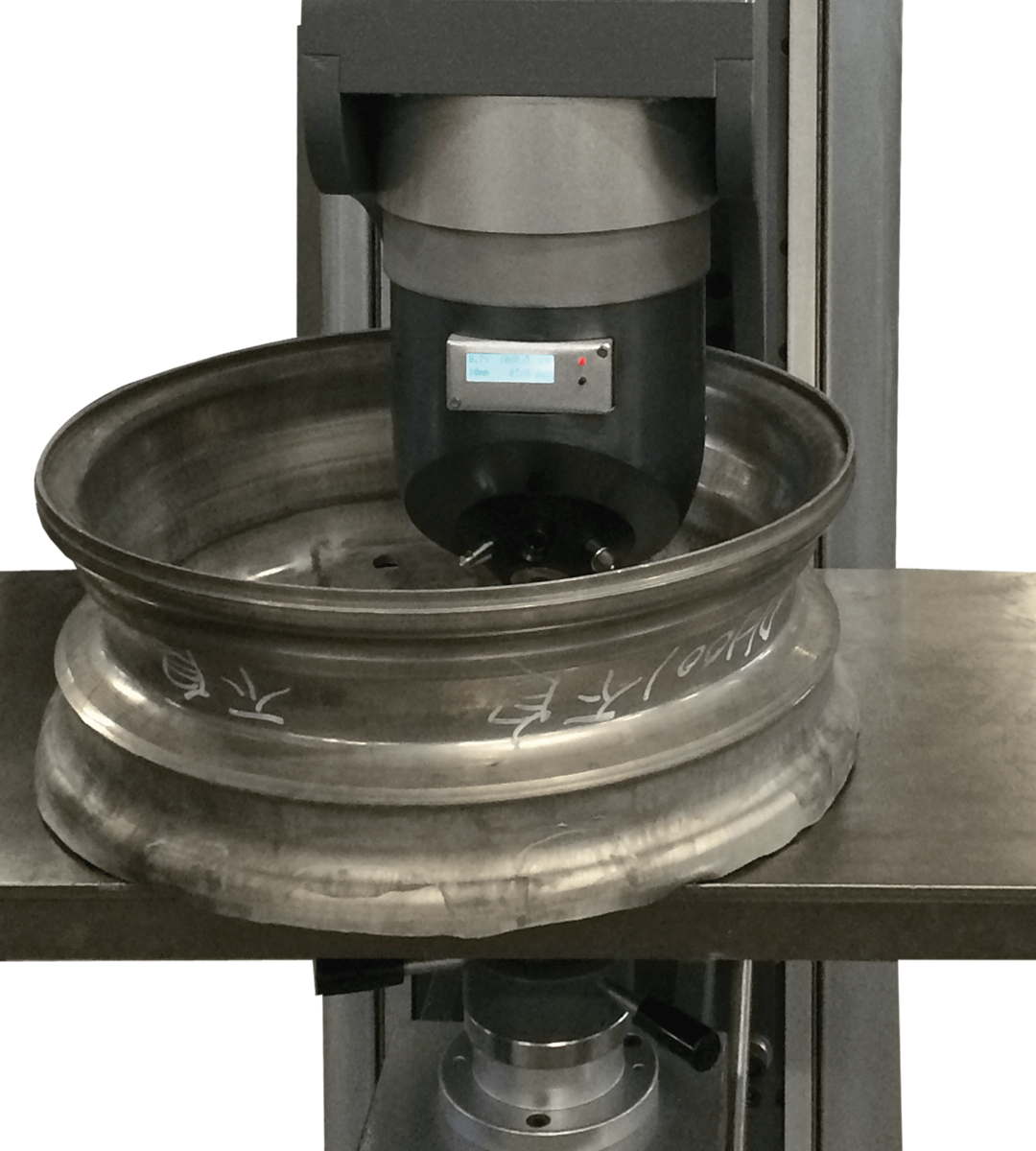

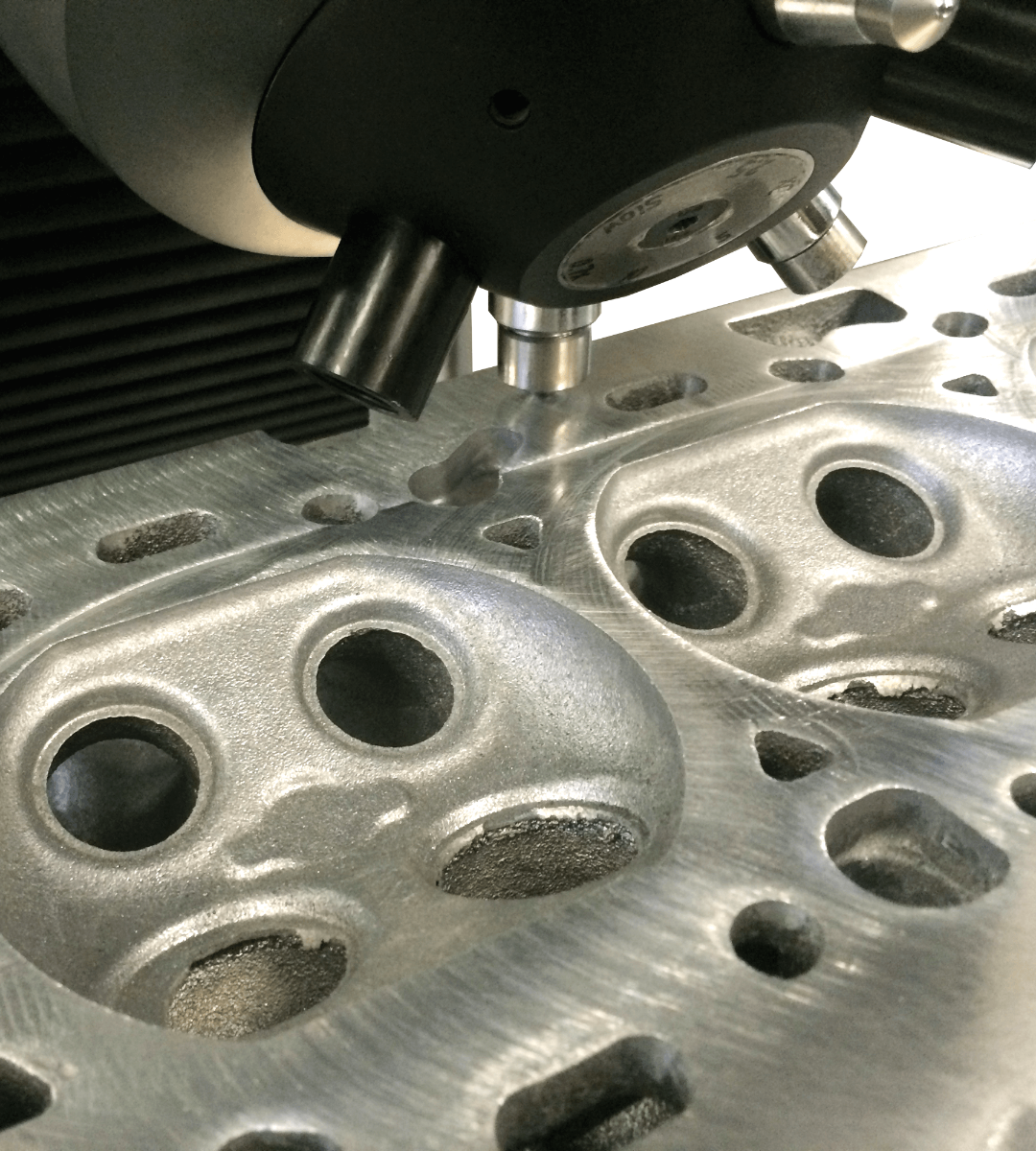

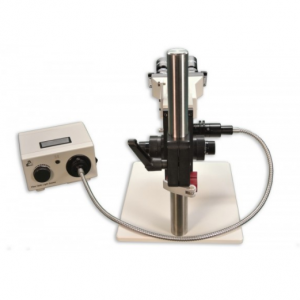

During each test the operator can return to the process at any time, either to continue the series of measurements, either to do a specific test or to start a new series. EAGLE 3000 can send data at any time to a printer or via the network. The image of each impression can be stored allowing immediate control of the measurement even long after the protocol has been issued or the data has been distributed over the network. EAGLE 3000 allows you to choose between 4 languages: English, French, German and Italian. It is possible to obtain other languages on request. EAGLE 3000 has been designed to allow maintenance and/or repair operations with extreme speed and simplicity. The high precision of the 45° automatic revolver system for the rotation of the lens-penetrator group guarantees the exact positioning of the lens on the impression and the consequent positioning of the image on the monitor. EAGLE 3000 is equipped with an industrial PC integrated with Windows platform; it has a USB camera of 3 mega pixels. The software allows the fully automatic measurement of all impressions, leaving the operator the freedom to perform the measurement manually.

Technical data

| Working principle | Brinell |

| Loads | 31,25kgf (306.5N), 62,5kgf (612.9N), 125kgf (1226N), 187,5kgf (1839N), 250kgf (2452N), 500kgf (4903N), 750kgf (7355N), 1000kgf (9817N), 3000kgf (2942N) |

| Norms and certifications | DIN EN ISO 6506, ASTM E 10 |

| Load time | selectable from 3 to 30 sec. |

| Load application method | electric motor in closed control circuit with dynamometric cell |

| Optics | 0.7x and 3x lenses |

| Languages | Italian, English, German, Other languages on request |

| Output interfaces | USB 2.0, ETHERNET |

| Power supply | 230 V, 50 Hz (220 VA) |

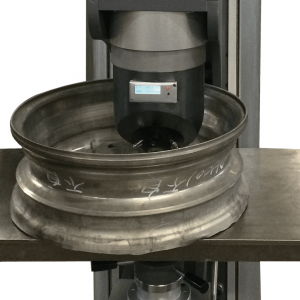

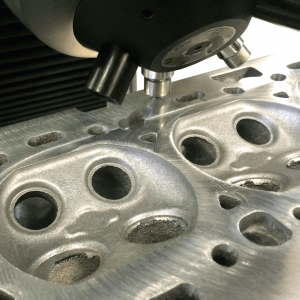

| Working area dimensions | H max 1.200 mm H max with elevating screw 600 mm H max with intermediate table w/o elevating screw 800 mm Outreach 300 mm |

| Overall dimensions | H 2046mm W 1303mm (with extended monitor) L 752mm |