GENERAL CHARACTERISTICS

• Dim. mm approx (HxLxW) : 400x600x100

• Weight approx. kg 15

• Input power supply: AC 220V±10% 50 Hz

• Working temperature: -40℃ ~ +50℃.

MAIN CHARACTERISTICS

It is possible to cover the following subjects:

• General structure of the management system for a gasoline engine

• Composition of the exhaust gases in Otto cycle engines

• Preparation and control of the fuel

• Lambda regulation

• Re-circulation of the exhaust gases, anti evaporation of the fuel and thermal post combustion

• Sensors and actuators used in the systems for reducing the exhaust gas

• Control unit (ECU) and CAN-BUS

• Analysis of the electric signals of sensors and actuators

• Troubleshooting with traditional instruments

• Troubleshooting with OBD self-diagnosis

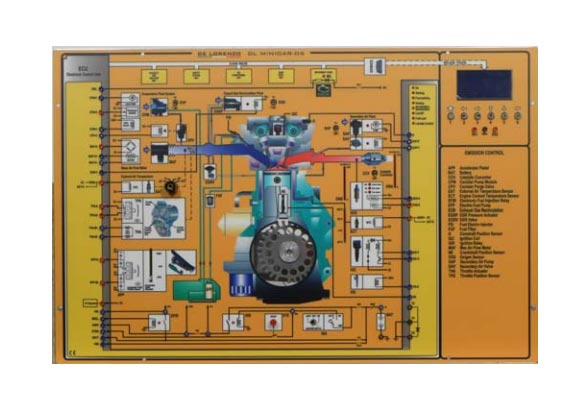

EMISSION CONTROL MINICAR

This simulation panel deals with studies the devices and the systems used for controlling and reducing the emissions of gasoline engines.

In fact, the combustion of the fuel inside the cylinders of an engine is incomplete.

The more it is incomplete, the higher the emission of noxious components that are present in the exhaust gas of the engine.

The trainer is provided with an electric motor, with phonic wheel and magnetic sensor for position and rotation speed.

The electric motor ‘simulates’ the operation of the real engine (all the operations are made at a speed 10 times lower than the real one of the engine: between 80 and 600 rpm).

This allows visualizing on LED the operation of the different devices: spark plugs, injectors, etc. On the LCD display the actual speeds are visualized (rpm from 800 to 6000).

All the signals (on LED and terminals) are synchronized with the rotation of the phonic wheel and this makes ‘real’ the operation of the trainer.