TRAINING OBJECTIVES

• Thermodynamic fundamentals of cooling tower • Measuring the air flow, air and water temperatures and of humidity

• Changes of state of the air in a h-x chart

• Determination of the cooling capacity

• Energy balances

• Calculation of process parameters such as cooling distance limit, width of the cooling zone, etc.

TECHNICAL DATA

• Cross section: 150×150 mm.

• Air flow measurement by calibrated orifice Ø80mm.

• Three steps adjustable heater: 0,5kW, 1kW and 1.5kW.

• Maximum hot water temperature: 60°C.

• Centrifugal fan:

– Power consumption: 90W.

– Maximum air flow: 510m3 /h.

• Peripheral pump:

– Maximum flow: 10 l/min (5m M WC)

– Power consumption: 180W.

• Hot water circuit with bypass.

• Electronic regulation of the hot water flow and airflow through the computer system.

• The unit is supplied with an electronic control system with visualization and a computer system with software.

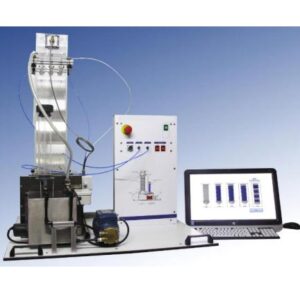

WATER COOLING TOWER

The trainer is designed to demonstrate the most widespread cooling method in industry.

The demonstrated method shows the cooling of hot water to room temperature.

Air at room temperature is introduced by a fan from the lower part of the system at the bottom of the tower.

While hot water is sprayed in the upper section of the tower, hot water cools down until it reaches room temperature, then it is reheated and the process starts again.

The unit is supplied with a personal computer.