OPERATION OF THE PLANT / TECHNICAL FEATURES

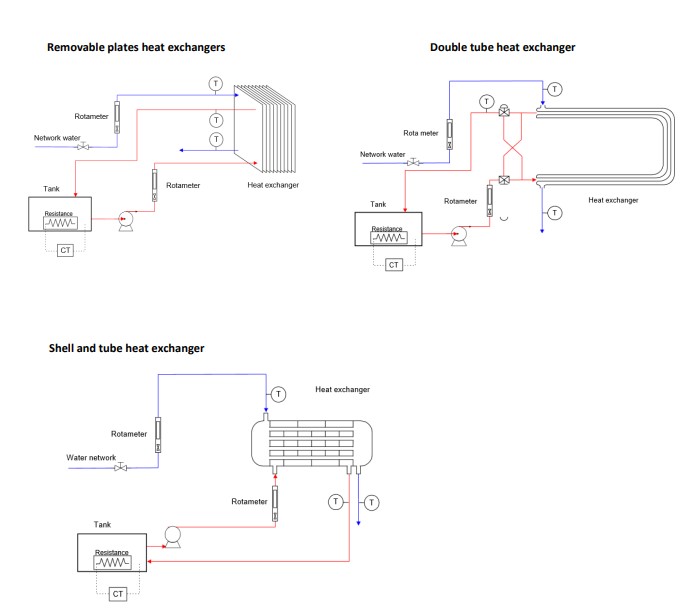

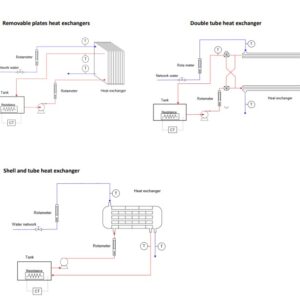

The plant allows a comparison among the three most common types of heat exchangers:

- Plates heat exchanger

- Concentric tubes heat exchanger

- Shell and tubes heat exchanger

The principle of the heat exchangers is based on the transmission of heat energy between two fluids at different temperatures through the separation surface between the two ducts, so that the fluid at higher temperature transfers heat to the fluid at lower temperature. In this way, both temperatures tend to equalize, and the desired objective is obtained, that will be in one case to heat a fluid and in the other one to cool it. There are many and different devices designed to provide or to remove heat, although the ones that are listed below represent the three typical systems of heat exchangers:

Removable plates heat exchangers

It is the most effective system for exchanging heat. It is based on a series of plates mounted in parallel, machined in such a way to form between them chambers through which, in separate circuits, pass the refrigerant liquid and the liquid to be refrigerated. The performance of such a system is very high because it has a very large heat exchange surface and a limited external volume. It is also very easy to be maintained and cleaned.

Double tube heat exchangers

It consists of two concentric tubes, through which a fluid circulates inside the inner tube and another fluid through the annular space. The two fluids exchange heat through the wall that divides them. These systems are used for small heat flows.

Shell and tube heat exchangers

They are composed of a cylindrical housing inside which there is a bundle of tubes of small diameter, parallel to the axis of the cylinder. A fluid circulates through the interior of the tubes, while the second fluid circulates inside the housing, bathing the bundle of tubes by their outer wall. At the ends of the bundle of tubes we have the heads of the exchanger that allow distributing the fluid that circulates through the tubes. Several baffles placed in the housing causes the external fluid to circulate in the direction as perpendicular as possible to the bundle of tubes, and this improves the heat transfer.

If the two fluids enter from different ends of the exchanger, they circulate through the unit in opposite directions. This type of flow is commonly used and is called a counter flow or just counter stream. If the two fluids enter from the same end of the exchanger and flow in the same direction from one end to the other, the flow is called parallel streams.

DIMENSIONS OF THE PLANT

The plant is mounted on a tabletop frame made of stainless steel and containing the three described systems and the necessary accessories.

Approximate dimensions: 1320 x 590 x 330 mm., made with 30 x 30 x 2 mm. tube.