TRAINING OBJECTIVES

• Determine the characteristic curves of a pump at different working speeds.

– Height – flow volume (H-Q)

TECHNICAL DATA

Pump characteristics:

• Maximum manometric head: 22M WC

• Flow volume: 10 / 80 l/min

• H: 21.9 M WC

• Max. power: 370W (0.5 HP)

• Max. speed: 3.450 RPM

Pressure gauges:

• Bourdon manometer 0-60 M WC

• Bourdon vacuum pressure gauge (-10) – 45 M WC

Variable frequency drive:

• Rated power: 0.37kW

• Output current: 2.2A

• Rated voltage: 110V

• Frequency: 60Hz

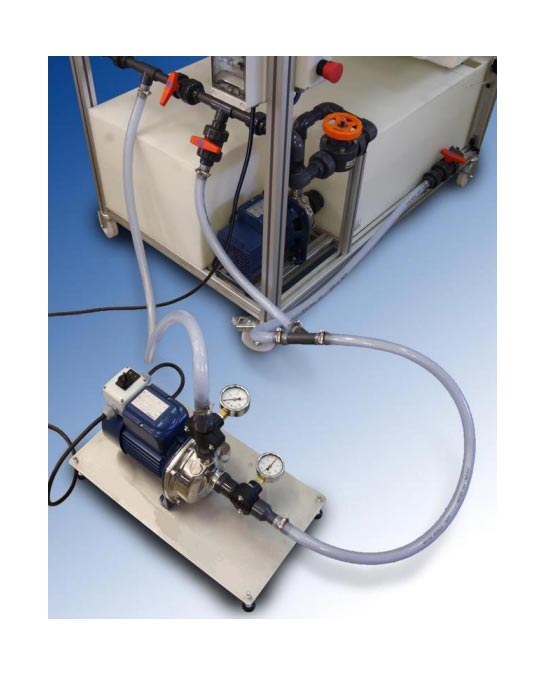

CENTRIFUGAL PUMP – MODULE

The pumps in a pipe system convert mechanical energy into hydraulic energy.

This additional energy allows a fluid to move from one location to another when it is not possible to flow by gravity.

For example, to raise a fluid at a certain height above the pump or recycle it in a closed system.

In general, the main purpose of a pump in a system is to increase the total energy in quantity H.

The fluid is collected and contained by the pump casing, which drives the fluid by its outline shape to the outlet pipes or to another impelling stage.

This system allows studying the characteristics of a pump working individually at different rotational speeds.

This is made possible by a frequency inverter which adjusts the working speed according to each case study.

In addition, the flow control valve manages the pump operating mode, so it is possible to obtain experimental operating curves.

These curves can be compared with those supplied by the manufacturer, as well as those obtained by mathematical calculation.