GENERAL CHARACTERISTICS

• Dim. mm approx (HxLxW) : 700x1000x150 – (470 with the base)

• Weight approx. kg 25

• Input power supply: AC 220V±10% 50 Hz

• Working temperature: -40℃ ~ +50℃.

MAIN CHARACTERISTICS

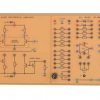

The simulator covers the following topics:

• Oxygen sensor, temperature sensor, MAP sensor, MAF sensor, knock sensor, operation.

• Pressure, flow, position sensors.

• Injection time – calculation.

• Ignition pulses effect on main switch, ignition timings.

• Engine efficiencies, horsepower and engine torque, valve position switch output signals and valve position sensor output signals.

• Signal analysis, injector activation signal at various conditions, air injection control, injection duration at various speeds, temperatures and engine loads.

• Air temperature effect on the quantity of injected fuel.

• Fuel cut-off, relationship between the duration of injector opening to the quantity of injected fuel.

• Solenoids, open and close loop controls and exhaust gas circuit.

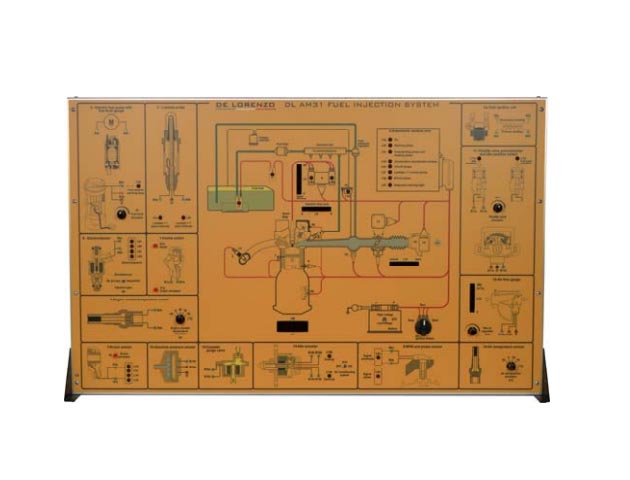

This vertical frame bench-top trainer is specially designed to show to students how automotive systems work. The simulator consists of a panel operated by the support of a computer with a coloured silk-screen diagram that clearly shows the structure of the system and allows the location of the components on it.

The trainer is supplied with a CAI Software and the supported documentation guides the students to the study and the performance of the simulation exercises. All components installed and given leads are made to protect the safety of the students

HYBRID AND ELECTRIC SYSTEMS

This simulation panel allows to study engine operation, engine sensors and controls and electronic fuel injection. The simulator takes into consideration all these aspects by performing the following functions:

• Ignition phase

• Heating phase

• Lambda regulation

• Quick acceleration/deceleration phases

• Cut-off phase

• Regulation of the injection time

• Regulation of the advance angle

• Regulation of the minimum rpm

• Regulation of the knock

Limitation of the rpm In particular, also the following components are analysed:

• Rpm/reference point sensors

• Level sensor

• Inertial sensor

• Electro-pump

• Idle actuator

• Electro-injectors and coils.