PAX-it has many powerful image analysis features including:

- ASTM Grain Size Analysis

- Plating, Coating & other Layer Thickness

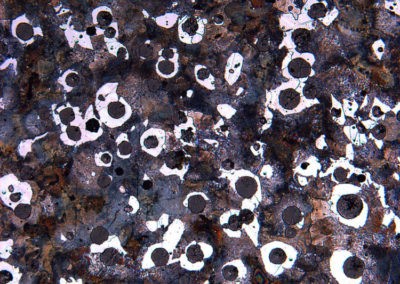

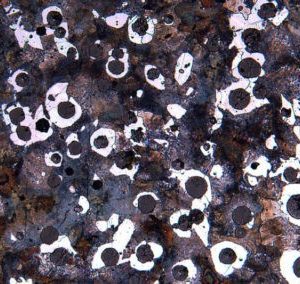

- Particle Counts and Size Distribution

- Area Fractions

- Porosity

- Nodularity

- Ferrite/Pearlite

- ASTM Flake Size Classification

- & more

PAX-it metallography software will improve your workflow for analysis of powdered metal, graphite in cast iron, heat treat, gray iron, powder metal, copper, and many other materials. Specific user-defined routines may be established for numerous materials including martensite, pearlite, ferrite, austenite, and many others, according to your own samples, sample prep, and optical setup. Easily capture, tag, annotate and archive images into your PAX-it database, all in one step. Then use PAX-it’s powerful image processing tools to capture those hard-to-view samples. With just a few clicks of the mouse, you can manually measure features including lines, angles, areas, arcs, and more. Or, perform automated image analysis on your samples to detect and classify the features of interest.

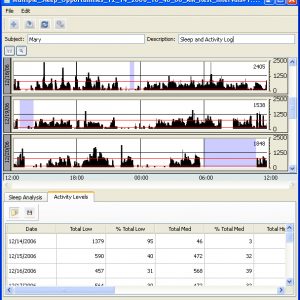

Information stored in PAX-it is in a searchable database, allowing for quick retrieval of samples for a customer or co-worker. Answers come in seconds, rather than hours, as the results of your customized searches are displayed immediately on the computer screen, readily available for reporting and sharing.

Commercial labs, contract labs, universities, and government facilities all use PAX-it and PAXcam to document, analyze, and archive their metallurgical samples. Save money and time by using PAX-it to quickly create professional metallurgy reports.

PAX-it makes creating reports easy with its report generation link to powerful applications such as Microsoft Word® and Excel®, allowing you to incorporate your images, data, summary stats, and graphs directly into customizable report templates.

Immediate sharing of images, data, and reports can be accomplished by taking advantage of PAX-it’s one-click export and email features. In addition, the Network Site License option allows users to capture and save their metallurgy or metallography images to the network, so that the analyses and reporting can be done at their desks, with the results immediately available for others to view.