| NanoGenizer High Pressure Homogenizer: | |||||

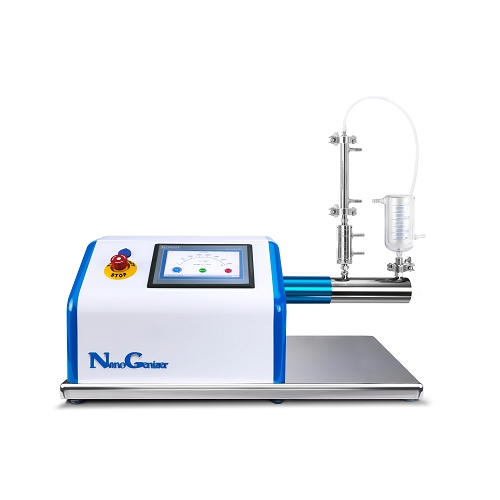

| NanoGenizer is a laboratory high pressure processing device. It is an electrically-driven and bench-top, high pressure homogenizer requiring no compressed air or hydraulic oil to achieve maximum 3,062 bar (45,000 psi) operating pressure.

NanoGenizer high pressure homogenizer is composed of a feed reservoir, high pressure pump, transducer, PLC control panel and microfluidics diamond interaction chamber. The sanitary pump system of the NanoGenizer high pressure homogenizer is able to supply the desired pressure to the product stream and push it through the micron chamber (microreactor) to create high shear rates and strong impact within the stream. This process results in uniform particle distribution and smaller particle sizes. |

|||||

| Application of NanoGenizer High Pressure Homogenizer: | |||||

| Cell disruption and particle size reduction Nano emulsions Nano dispersions Liposomes Deagglomeration Vaccine production |

|||||

| Performance of NanoGenizer High Pressure Homogenizer: | |||||

| Energy efficient, 1/2 energy loss of the most homogenizers Small (integrated design delivers the light weight and small dimensions) Smart (programming control systems confer diligent functions: controlled inlet volume ± 0.1mL; auto stop with time/volume) Silent (noiseless performance) Strong (more than 150 mL/min at 30,000 psi) CE compliant and RoHs compliant |

|||||

| Specifications | |||||

| Catalog No. | NG-45K | NG-30K | NG-25K | NG-20K | NG-15K |

| Flow Rate | 60mL/min | 100mL/min | 100mL/min | 150mL/min | 150mL/min |

| Min. Sample | 5mL | 5mL | 5mL | 5mL | 5mL |

| Max. Pressure | 45,000psi | 30,000psi | 25,000psi | 20,000psi | 15,000psi |

| Dimensions(cm) | 70 × 36 × 30 | 70 × 36 × 30 | 70 × 36 × 30 | 70 × 36 × 30 | 70 × 36 × 30 |

| Weight | 35 kg (75 lbs) | 35 kg (75 lbs) | 35 kg (75 lbs) | 35 kg (75 lbs) | 35 kg (75 lbs) |

| Max. Temp. | 80ºC (176ºF) | ||||

| Power | 110V/220V | ||||

| Cleaning | Flush to clean | ||||

| Application | Nano emulsion, fat emulsion, liposome, cell disruption, nano dispersion, deagglomeration | ||||

| Features | Digital display of pressure or pressure gauge | ||||

| Standard Features | |||||

| Parts | Y-type diamond interaction chamber with cooling option | ||||

| Control System | High pressure programming control systems®: touch screen, speed control, auto stop control by volume, time, pressure or temperature, settable volume control as low as 1mL, display of flow rate and time, overload protection | ||||

| Pressure Gauge | Digital display on the touch screen | ||||

| Inlet Type | 1/4″ HP coupling | ||||

| Outlet Type | 1/4″ HP coupling | ||||

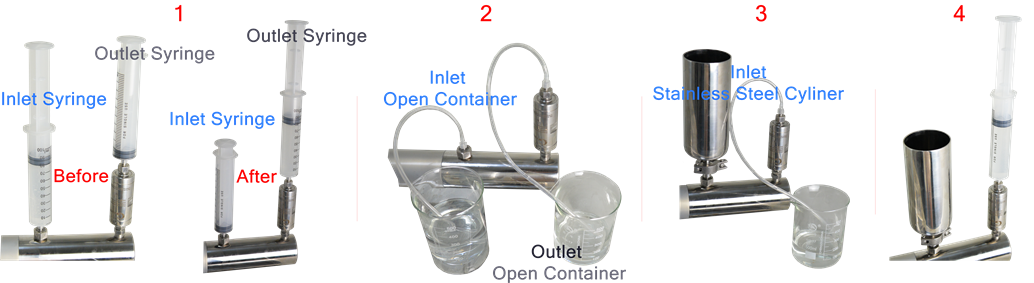

| Inlet Reservoir | 20mL syringe | ||||

| Outlet Reservoir | 20mL syringe | ||||

| Product Material | 316L stainless steel, tungsten carbide, viton, teflon | ||||

| Material Standard | Pharmaceutical grade, FDA, GMP | ||||

| Warranty | 1 year against any manufacturing defects | ||||

| Option Features | |||||

| Parts | High pressure extruders, homogenizing valves two stages, heat exchanger | ||||

| Control System | Mechanical control: speed, start, stop control | ||||

| Detector | Pressure gauge, pressure transducer, temperature transducer | ||||

| Outlet Type | Tri-clamp or luer | ||||

| Heat Exchanger | HPE-100-3D; HPE-150-3D; HPE-200-3D | ||||

| Liposome Extruder | GOE-200mL; GOE-1000mL | ||||

| Inlet Reservoir | 10mL, 20mL, 50mL, 100mL, 200mL, 500mL syringe, S/S cylinder, jacketed glass cylinder or online | ||||

| Outlet Reservoir | 10mL, 20mL, 50mL, 100mL, 200mL, 500mL syringe, S/S cylinder, jacketed glass cylinder or online | ||||

| Cylinder | Titanium high pressure cylinder (resistant to strong acid and base) | ||||

Outlet: syringe; open container; stainless steel cylinder