Technical Specifications

Structure

The plant is mounted on a structure made of 40x40x2 square tubes of stainless steel AISI 304. The total dimensions of the plant are 1100 mm. long and 650 mm. deep.

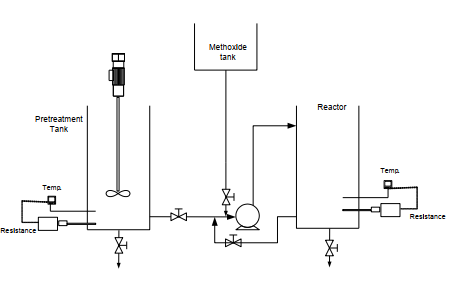

Methoxide tank

A 5 litre capacity tank made of plastic material in which the methoxide is stored.

Pre-treatment tank

The oil to be treated is stored in a stainless steel tank of 200 mm. diameter and 350 mm. height for a volume of about 10 liters. The tank is provided with flanged caps for easy dismantling and cleaning. It is used to perform the pretreatment of the oil, by means of a stirrer, a heating resistor and a temperature sensor with digital controller to maintain the desired value.

Reactor

The oil is transferred to the reactor by a metering pump with regulation of the flow, which is subsequently used to perform the recirculation in the reactor while the reaction takes place. This reactor is a stainless steel tank of 200 mm. diameter and 350 mm. height for a volume of about 10 liters. This tank is also provided with flanged caps for easy dismantling and cleaning

Pump

A peristaltic pump with adjustable flow rate that, by means of a valve system, is responsible for: the transfer of the oil from the tank to the reactor, the metering of the methoxide and the recirculation.

By means of the same metering pump the methoxide, coming from a tank of 5 liters. made of plastic material, is added to the reactor.

Electric Box

The inside of the box has all the necessary elements for the activation of the electrical components, as well as the necessary protections against electrical failures, like overloads, short circuits or currents that derive to earth, according to the electro-technical standard in force for the protection of people and equipment.

The activation switches of the various elements (Resistances, Stirrer, Pump) are located on the front.

There is also a general on-off switch and an emergency stop button.

The power supply is single-phase with neutral and earthing.

Complete with:

– User manual

– Experiment manual

– Documentation on stirrer, pump and temperature sensor.

Biodiesel production

The process to make biodiesel involves a chemical reaction. This means that the biodiesel industry is a chemical industry.

Those involved in making biodiesel must have a good understanding of the underlying chemistry to ensure they are making quality fuel in a safe manner. Biodiesel is an alternative fuel for diesel engines. It is produced by chemically reacting a vegetable oil or animal fat with an alcohol such as methanol or ethanol.

The vegetable oils and animal fats used to make biodiesel can come from virtually any source. All of these products consist of chemicals called triglycerides; so, biodiesel can be made from soybean oil, canola oil, beef tallow, and pork lard, and even from such exotic oils as walnut oil or avocado oil.

Even used cooking oil or waste oil can be used to make biodiesel. However, these oils present special challenges for the biodiesel production because they contain contaminants such as water, meat scraps, and breading that must be filtered out before the oil is converted to biodiesel. Methanol is the most common alcohol used for making biodiesel.

List of Experiments

Biodiesel synthesis and determination of the density of the product

Experiment 1 – Biodiesel synthesis from unused and used sunflower oil. Using methanol and sodium hydroxide.

Experiment 2 – Biodiesel synthesis from unused and used sunflower oil. Using methanol and potassium hydroxide.

Measurement of the biodiesel properties.

Experiment 1 – Cloud point.

Experiment 2 – Heat of combustion.

Experiment 3 – Viscosity.

Measurement of combustion pollution through the soot produced during:

The combustion of biodiesel.

Description of the process

Oil and glycerin are inserted In the pretreatment tank and heated to 50 °C, continuously stirring. The mixture is then settled and decanted to remove any impurities from the oil.

The oil is then heated to 70-90 °C until the bubbles disappear.

Then, by means of the pump, the oil is sent to the reactor and heated, while keeping the temperature between 50 and 55 °C.

Methanol and sodium are mixed in the methoxide tank.

The recirculation of the oil starts with the pump and is continued, while 75% of prepared methoxide is added in 1.5 hours. Let stand and decant.

The recirculation of the oil starts again, while 20% of the methoxide is added in 1.5 hours. Let stand and decant.

The recirculation of the oil starts again, while the remaining 5% of the methoxide is added in 1.5 hours. Let stand and decant. In this way biodiesel is obtained. The next step is to wash and purify it.