DESCRIPTION OF THE PLANT

All the elements of the plant are mounted on a structure of about 1 m. (W) x 3 m. (L) x 1 m. (H), made of 40x40square tube in AISI 304 stainless steel, provided with self‐locking wheels for easy movement and location.

The plant includes a cabinet where switches and other electric control elements and protections necessary to ensure the safety of people and equipment in accordance with current electrical regulations are installed.

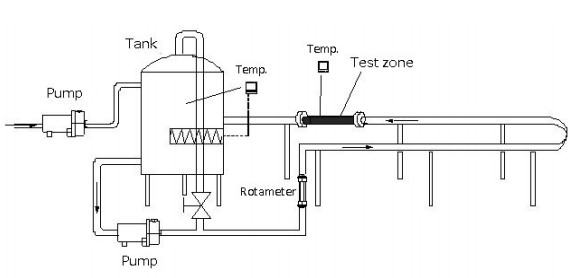

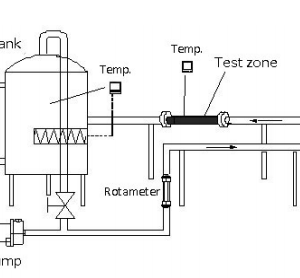

OPERATION OF THE PLANT

Water with suspended material is stored in a tank of 1000 L capacity made of stainless steel AISI 316, with drain valve and manhole for filling.

This tank is complete with stirring to keep the mixture in suspension, a heater for heating the fluid, a Pt‐100 sensor, and a digital controller for controlling the parameters in the tank.

The tank is thermally insulated to prevent heat loss. In order to fill the tank there is a centrifugal pump in stainless steel AISI 316 that gives a maximum flow of 45 m3 /h with a power of 1.5 kW.

The suspension is driven by a second centrifugal pump of stainless steel AISI 316 with similar characteristics to the previous one through a pipe of about 65 mm. diameter, U‐shaped, built in plastic material or stainless steel AISI 316 and is returned back to tank, thus creating a closed circuit. The recirculation flow of the liquid to the tank is controlled through a valve that regulates the flow of water driven to the pipe. The flow driven by the pump can be displayed on a rotameter.

At the end of this pipeline there is a pipe section that can be easily replaced by other pipe sections of different materials of 150 mm in diameter. In this section of pipe, specimens to be tested are inserted.

There is also a temperature probe Pt‐100 with relevant digital display.