TRAINING OBJECTIVES

Analysis of individual pumps:

• Determine the characteristic curves of a pump.

– Height – flow volume (H-Q)

Pumps analysis running in the same group:

• Characteristic curves in-series operation

– Height – flow volume (H-Q)

• Characteristic curves in-parallel operation

– Height – flow volume (H-Q)

TECHNICAL DATA

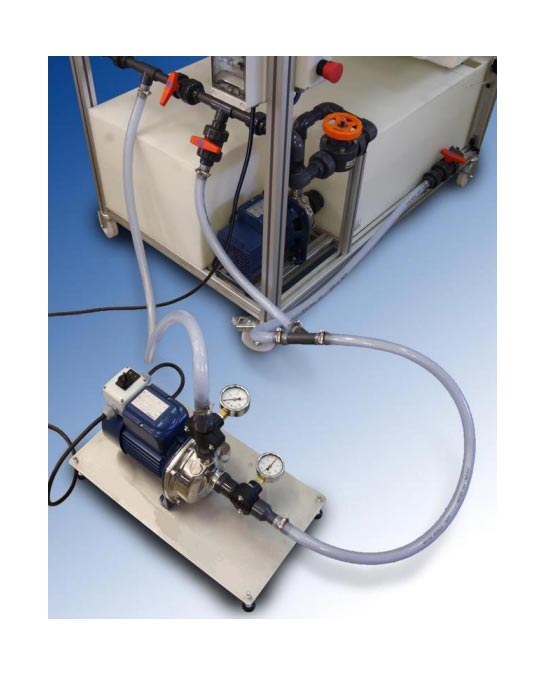

Pump characteristics:

• Maximum manometric head: 23 WMC

• Flow volume: 20/180l/min

• H: 31 / 16 WMC

• Max. power: 950W

• Max. speed: 3,450 RPM

Pressure gauges:

• Bourdon manometer 0-65 WMC

• Bourdon vacuum pressure gauge (-10) – 45 WMC

Tank:

• Capacity: 250 liters

SERIES PARALLEL PUMP

The pumps in a pipe system convert mechanical energy into hydraulic energy.

This additional energy allows a fluid to move from one location to another when not likely to flow by gravity.

For example, to raise a fluid at a certain height above the pump or recycle it in a closed system.

In general, the main purpose of a pump in a system is to increase the total energy in a quantity H.

The efficiency of a pumping system depends greatly on the type of pump configuration in series or in parallel as required by the system.

In addition, the flow control valve manages the pump operating mode, so it is possible to obtain experimental operating curves.

These curves can be compared with those supplied by the manufacturer, as well as with those obtained by mathematical calculation.

Furthermore, It is possible to experiment many operations such as the startup, the functioning, the operation and the regulation necessary in a pump installation.

The characteristics of a pump can also be studied when working individually or in groups.

The flow measurements are done by using the volumetric tank of the hydraulic bench (required), which is also possible to study the relationship between pressure loss and fluid speed.