TRAINING OBJECTIVES

• Balance of energies in the heat exchanger.

• Calculating the logarithmic average temperature difference.

• Determination of the overall transmission heat coefficient.

• Calculation of effectiveness.

TECHNICAL DATA

• Dimensions: 440x250x110 mm

• Number of plates: 7

• Heat transfer surface: 0,021 m²

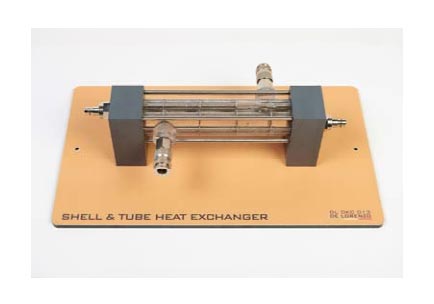

SHELL AND TUBE HEAT EXCHANGER

TECHNICAL DESCRIPTION

The shell and tube heat exchanger is one of the most used type in industry.

In this exchanger, the cold fluid passes through a number of parallel tubes and the hot fluid goes through a chamber containing the small cold tubes, thus producing heat transfer.

The advantage of this type of heat exchanger is the compact design and the possibility to work at higher pressures than other types.

This exchanger can operate with current or countercurrent flows.