TECHNICAL FEATURES

The Cathodic protection is a technique to control the corrosion of a metal surface by making it work as a cathode of an electrochemical cell. This is achieved by placing in contact with the metal to be protected another more easily corroded metal to act as the anode of the electrochemical cell.

Cathodic protection systems are most commonly used to protect steel, water or fuel pipelines and storage tanks, steel pier piles, ships, offshore oil platforms and onshore oil well casings.

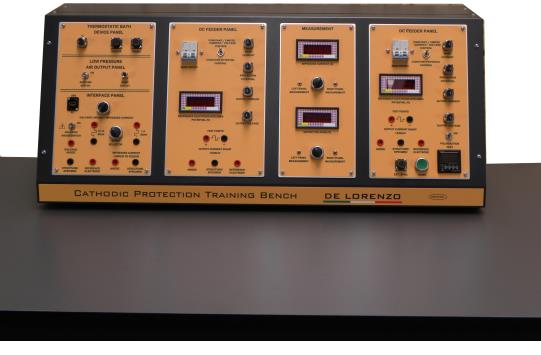

The bench is provided with measuring facilities characterized by suitable sensitivity and accuracy, in order to introduce which must be the basis of the laboratory tests to be executed, to recognize whichis the correct way in order to determine the behavior of a metal in contact with the electrolyte in different conditions of temperature (thermostatic bath) and in high oxygen concentration (air insufflations pump).

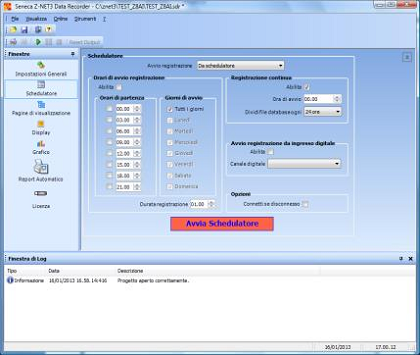

A suitable multi-channel interface can connect the bench to a PC in order to record the experiment results and give the trace for further studies.

LIST OF MATERIALS

Bench with wheels with electrical console to connect to the mains Vac supply and lockable shelves. Provided with waterproof top surface.

DC feeders (each provided with constant voltage, constant current, constant potential facilities). The relevant instruments are on the front console of the bench.

Digital voltmeter on console.

Digital ammeter on console.

PC interface for the measurement and record of 5 different channels.

Sets of 100 Safety gloves

Cu/CuSO4 portable reference electrode

Ag/AgCl portable reference electrode

5 Copper electrodes, 12x100mm, thickness 1mm

5 Carbon steel electrodes

3 Transparent basins to build the electrolytic test

Simple circuit with slliding resistor and lamp. Suitable for the insertion into the lectrical circuit of the electrolytic cell

10 Zinc electrodes diam 10×100 mm

10 Magnesium electrodes diam 20×100 mm

10 Aluminium electrodes

2 Fe/Si Anode 25mmx150mm

Cu rod diam 1mm, lenght 0,5m

Ag rod diam 1mm, lenght 0,5m

Fe rod diam 1mm, lenght 0,5m

Fe/Cr/Ni rod diam 1mm, lenght 0,5m

Resistivity fluid cell

Waterproof resistor

Relevant sprayer (to connect to air pump on the bench)

5 Carbon steel electrodes (completely coated with epoxy compound)

8 Various Reagents in plastic cans (0,25kg or 0,100 kg/each) with technical sheet

Electronic pH meter

Set of spare fuse

5 Set of ancillaries and connecting leads

Paper copies and CD of the manual book for training of the teacher in order to undertake the experiments

Average training hours: 15h.

Approx. packing dimensions: 0.62 x 1.21 x 0.82 m.

Net weight: 51 kg.

Complete with:

User and experiments manuals.

PC interface and software for data acquisition.

ALTERNATIVE:

DL MK1

Cathodic protection training bench.

NOTE:

The DL MK2 version of the Cathodic Protection trainer differs from the DL MK1 version on the possibility of performing simultaneously the same experiment with different values of the parameters. In the DL MK2 version, the experiments can be performed in sequential mode, that is, if you want to change the value of a specific parameter, you can do it after performing the same experiment with the previous value. You must then record the results on your notebook and then compare the different results. With the DL MK1 version you can perform the same experiment with two different parameter configurations at the same time.