DESCRIPTION OF THE PLANT

All the items of the plant are located on a structure of stainless steel AISI 304 with self‐locking wheels. The external dimensions are approximately: 860 mm. height, 1000 mm. width and 550 mm. depth.

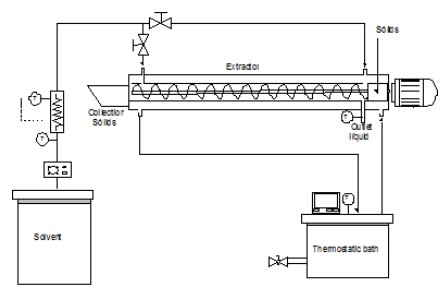

Below is a flow chart where you can see the elements and connections between them.

OPERATION OF THE PLANT / TECHNICAL FEATURES

The core of the plant is a stainless steel column of 600 mm. of working length, 100 mm. in diameter and 80 mm. screw diameter; the column has an outer jacket to control the extraction temperature. The extractor heating is achieved by the passage through the outer jacket of the water coming from a thermostatic bath of 20 l. capacity with analog temperature control from the ambient temperature up to 100 °C. This bath has a safety thermostat and a level float that switches off the heating in absence of liquid. The outlet of the jacket water goes back to the tank, thus creating a closed circuit. At the same time the column is mounted on screwed legs to modify the pitch of the reactor. The solids are stored in a hopper located above the extraction column made of stainless steel, being possible to adjust the inlet of the solids in the plant by modifying the number of revolutions per minute of the screw. The movement and the contact of the solid with the liquid is favored by an endless screw driven by a gear motor, that includes a drive controller for changing the rpm; the liquid inlet flows in counter current or in parallel to the inlet of the solid. The treated solids are collected in a plastic tray. The solvent is stored in a plastic tank of 20 l. capacity and is introduced into the extractor by a controlled flow peristaltic pump. The equipment includes a system for preheating the solvent, independently on the heating system for the extractor, composed of a temperature probe, a heating resistance and a PID controller. The plant is complete with Pt100 temperature probes and their corresponding digital displays for measuring the inlet and outlet temperature of solvent and extract.

The plant also includes a cabinet where there are the switches for the activation of the various elements by the user and the electrical control elements and protections required under the Low Voltage Electro‐technical Regulations and Rules of Machines to ensure the safety of people and equipment, switches, circuit breakers, differential switches, mushroom emergency stop, etc.