| 330TR | 330 | 280 | ||

| Centres | Height | 170mm | 170mm | 145mm |

| Admits between | – | 500mm | 500mm | |

| Or | 750mm | 750mm | 750mm | |

| Or | 1000mm | 1000mm | 1000mm | |

| Swing (diameter) | Overbed & saddle wings | 330mm | 330mm | 280mm |

| Over cross slide | 230mm | 230mm | 178mm | |

| Over tool slide | 48mm | 48mm | 48mm | |

| Spindle | Bored to pass | 35mm | 35mm | 35mm |

| Nose | N0.3-DI Camlock | N0.3-DI Camlock | N0.3-DI Camlock | |

| Taper in nose | N0.41/2 ASAB5.10 | N0.41/2 ASAB5.10 | N0.41/2 ASAB5.10 | |

| Taper in bush | N0.3 Morse | N0.3 Morse | N0.3 Morse | |

| Motor & Speeds | 3 Phase supply only | Standard | Standard | Standard |

| 1.5kw | Standard | Optional | Optional | |

| 1.1kw | Optional | Standard | Standard | |

| 2 Speed Motor | 1.9/.95kW | Optional | Optional | Optional |

| Bed | Width over ways | 190mm | 190mm | 190mm |

| Cross Slide | Width | 140mm | 140mm | 140mm |

| Travel | 175mm | 175mm | 175mm | |

| Tool Slide | Width | 75mm | 75mm | 75mm |

| Travel | 95mm | 95mm | 95mm | |

| Tool | Max. section | 16mm | 16mm | 12mm |

| Tailstock | Quill diameter | 37mm | 37mm | 37mm |

| Travel | 95mm | 95mm | 95mm | |

| Internal taper | N0.3 Morse | N0.3 Morse | N0.3 Morse | |

| Set over | 10mm | 10mm | 10mm | |

| Leadscrew | Diameter | 25mm | 25mm | 25mm |

| Thread | 6mm Pitch | 6mm Pitch | 6mm Pitch | |

| Or | 4TPI | 4TPI | 4TPI | |

| Feeds | Without recourse to changewheels |

12 | 12 | 12 |

| Changes | 12 | 12 | 12 | |

| Range (Longitudinal) from | .012mm per rev | .012mm per rev | .012mm per rev | |

| Cross feeds one half to of longitudinal values |

•6mm per rev | •6mm per rev | •6mm per rev | |

| Threads | (1) With set of 9 changewheels (Standard on 330TR/330) |

73 | 73 | 73 |

| 39 Metric pitches | •2-7mm | •2-7mm | •2-7mm | |

| 34 English pitches | 3.5-128 TPI | 3.5-128 TPI | 3.5-128 TPI | |

| (2) With 4 additional wheels BA (British Assoc.) pitches |

0-8 BA | 0-8 BA | 0-8 BA | |

| (3) With 2 additional wheels and aux. changewheel stud |

||||

| Module pitches | .3-2 MOD (12) | .3-2 MOD (12) | .3-2 MOD (12) | |

| D.p. (diametral pitch) | 14-60 DP (24) | 14-60 DP (24) | 14-60 DP (24) | |

| Machine Weight | Model 500mm | – | 350kg | 330kg |

| Between Centres | Model 750mm | 400kg | 400kg | 380kg |

| Model 1000mm | 450kg | 450kg | 400kg | |

| Packing Case | Model 500mm | 139 X 95 X 140cms | ||

| Dimensions | Model 750mm | 164 X 95 X 140cms | ||

| Between Centres | Model 1000mm | 190 X 95 X 140cms | ||

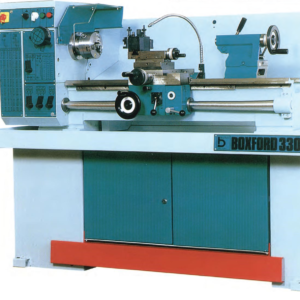

Boxford Lathes

Lathe Features

| SAFETY | FEED GEARBOX |

| Emergency stop push button (Strategically placed) | Grey iron casting |

| Emergency stop/isolator (Padlockable in off position) | Enclosed and fully lubricated unit |

| Electrical kickstop option (standard on 330TR) | Lever feed selection for whole range with half, plus 50%, double and 8:1 multipliers |

| Interlocked electrical panel opening | Hardened and tempered alloy steel gears |

| No volt supply protection | Ball-bearing shafts |

| Electrically interlocked chuck guard | Low periphery speeds |

| Electrically interlocked end drive cover | LEADSCREWS |

| Protection on direct spindle reverse | Large diameter |

| Telescopic leadscrew covers | Sealed for life ball bearings |

| Rear splash/chip guard as standard | APRON |

| Interlocked feed and thread engagement | Grey iron casting |

| Omni directional feed and thread disengagement | Enclosed and fully lubricated unit |

| Feed slipping clutch at apron | Push-pull feed axis selector |

| Shear pin in end drive | Cam lever-feed engagement with adjustable feed slipping force |

| Tailstock travel stop on bed | Graduated handwheel dial |

| Spindle tail end cover | Thread dial indicator |

| BED | SADDLE AND SLIDES |

| Hardened and ground | Adjustable gibs |

| Excellent swarf clearance | Backlash eliminator |

| HEADSTOCK | Tee slot tool slide |

| Grey iron casting – with ‘Vee’ location on bed | Cross and topslide locks |

| Centralised direct reading speed selector | Ball lubrication points |

| Oil sump lubrication with oil level sight glass | Moulded bedway wipers |

| Ball bearing lay shafts | Diameter reading cross slide dial |

| Hardened alloy-steel gearing (‘Reishauer’ ground where appropriate) |

Hole-grid for attachments on cross slide |

| Sliding gears on lay shafts only | TAILSTOCK |

| Low input RPM | Dual graduated quill |

| Low periphery speeds | Hardened morse taper |

| Hardened spindle nose and internal tape | Graduated handwheel dia |

| Internal feed reverse gearing | Ball lubrication points |

| Low output RPM to end drive | Set over adjustment with scale |

| CABINET | Moulded bedway wiper |

| All steel construction | Quill retaining mechanism |

| Capacious storage cupboard | |

| Locking doors | |

| Full water tight swarf tray. |

Accessories and Additional Equipment

• Additional Chucks

• Work Driver/Faceplate*

• Spindle Bush and Centre*

• 280/300mm dia. Faceplates

• 4 way Square Toolpost

• Emergency Stop Foot Bar**

• Steadies

• Rotating Centre

• Drill Chuck and Sleeve

• Dual Reading Dial**

• Coolant**

• Low Voltage Lighting

• High Speed Threading Attachment

• Hydraulic Copying Attachment

• Longitudinal and Cross Stops

• Micrometer Stop

• Travelling Work Guards

• Auxiliary Rear Slide

• Milling/Boring Table

• Taper Turning Attachment

• Toolpost Grinder

• Collet Attachments

• Apron Rod Spindle Control

• Spindle brake**

• Digital Readout

* Standard on 330/330TR

** Standard on 330TR only